Dynamic UK Technology and Manufacturing consortium is proud to introduce its APC-17 supported project e-MOTIF.

e-MOTIF (electric motor with integrated inverter and flywheel energy storage) will bring to market a truly scalable family of e-modules. E-modules are electric motors with fully integrated power electronics.

These e-modules can be easily tailored for hybrid and e-axle applications and provide full integration with F-Boost, Flybrid’s exciting flywheel energy storage technology.

EMPEL Systems, PUNCH-Flybrid & Shield Engineering Group bring together a unique blend of market-leading resources to deliver an exciting new family of products which will not only deliver excellent emissions reductions but will enable clients to bring their vehicles to market without compromise and with cost-effective new product introduction programmes.

Working extremely closely together, and including joint-venture operations between the partners the consortium delivers:

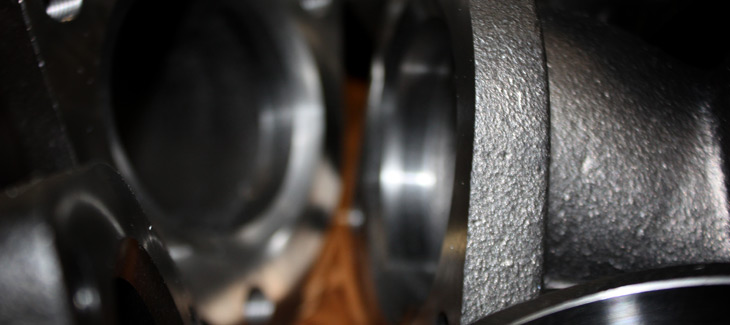

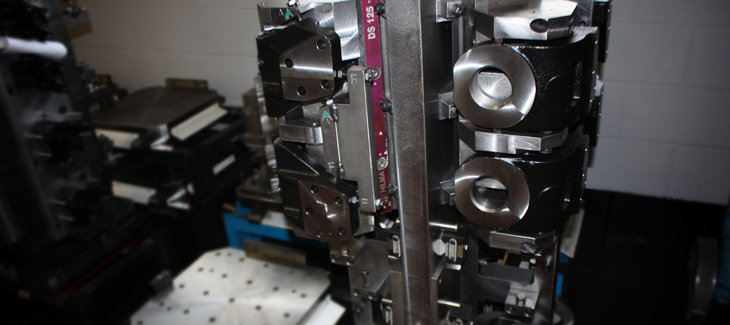

- Class-leading e-motor design and development using the latest, most-powerful design and analysis tools.

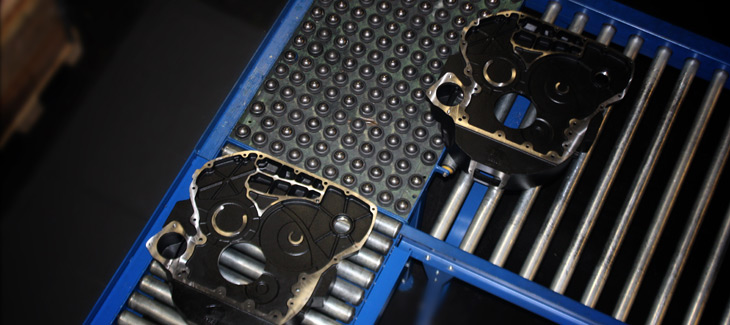

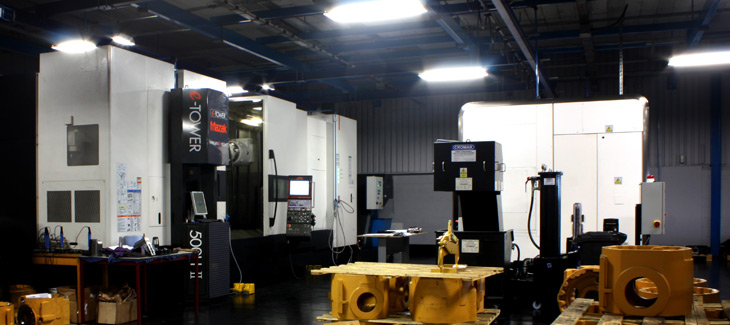

- The UK’s largest independent manufacturer of quality machined components and complex assemblies with extensive in-house high-pressure, low-pressure and gravity aluminium die-casting.

- Proven flywheel energy storage technology which enables an extremely power-dense solution for challenging duty cycles delivering significant emissions reductions while avoiding battery up-sizing.

- Low-cost, high and low voltage power electronics which are designed for full integration with e-motors and with a low-risk supply chain.

- UK manufacturing and technology centres scaled to support the UK’s rapidly growing status a centre of excellence in electrification.

- Significant UK Midlands based job opportunities and personal development across a range of disciplines.

With support from the Advanced Propulsion Centre, off-tool and off-process production capability will be established during 2022 with opportunities for customer production commencing in 2023.

Applications which will benefit from this e-module and F-Boost technology and flexibility include:

- Passenger and Sports Car – BEV, HEV, PHEV

- Light Commercial Vehicles – BEV, HEV, PHEV

- HGV and PSV – BEV, HEV, PHEV

- Power Generation

- Construction Equipment

- Marine

- Aerospace

Tailored production is achieved through truly scalable architecture which results in minimised product specific investment for clients. This is coupled with accelerated product definition and new product introduction timing. In many cases deeper integration into customer systems is also achievable.

The technologies employed already meet challenging 2035 Automotive Council Targets for weight, cost, and efficiency.

Initially, installed capacity for 20,000 e-modules per annum is scheduled from 2023 however with the scalable architecture and equally scalable manufacturing technologies greater annual volumes can be accommodated.

A second much higher UK based volume manufacturing facility is planned with ramp-ups possible as early as 2025 avoiding any disruption to any live products.

For more information please contact:

info@shield-smt.co.uk

info@empelsystems.com

info@punchflybrid.com

APC backing announced for exciting £11.3M collaborative electric and kinetic energy innovation project

Shield Manufacturing Technologies is delighted to share APC’s announcement that it is leading the innovative midlands-based e-MOTIF manufacturing project, one of just three projects awarded by the Advanced Propulsion Centre UK.

Together with our partners EMPEL Systems PFS Manufacturing and PUNCH Flybrid, we will be developing a family of power-dense e-modules comprising electric motors with fully integrated inverters that will be used in flywheel energy storage systems and Electric Drive Units for deployment in passenger cars as well as commercial vehicles.

The other two winners of the competition are Wrightbus developing hydrogen buses & Meritor developing electric powertrains for heavy goods vehicles. Shield would like to congratulate these consortia and we look forward to seeing their projects progress.

FOSSE WAY

Tel: 01162 460660,

365 Fosse Way,

Syston, Leicester,

LE7 1NL

Wenlock Way, Leicester,

LE4 9HU

Tel: 024 7636 2371,

Torrington Avenue, Coventry,

CV4 9AP

Tel: 0116 244 0400,

140 Barkby Rd, Leicester

LE4 9LFTel: 01536 216929,

Station Road, Burton Latimer

Northamptonshire, NN15 5JP

Tel: 0161 785 5100,

Dowry Park Ind Estate, Turner St. Lees, Oldham. OL43NU

Tel: 01455 612521,

Plots 1 & 2, Sketchley Lane Industrial Estate, Sketchley Meadows, Hinckley LE10 3EN.

Tel: +441926817167

Welsh Rd, Southam Warwickshire, CV47 1NA

Tel: 0121 556 0995

84 Bridge St, Wednesbury WS10 0AN.

Tel: +32 51 22 88 08

Moorseelsesteenweg 206, 8800 Roeselare, Belgium

400,000 + Sq ft

Low to high